-

Ball bearings are the most common and most used type of bearing found in a number of objects. Also known as anti-riction

bearings, ball bearings are small metallic or ceramic spheres used to reduce friction between axles and shafts in numerous

applications. These bearings are able to handle both thrust and radial loads, and are used for applications where the load is

relatively small. Load in a ball bearing is transmitted from the outer surface to the ball, and from the ball to the inner surface

Since the ball is spherical in shape, it contacts the inner and outer race at a very small point, which helps it spin evenly and

smoothly. But the contact area holding that load is very small, so if the bearing is overloaded then the balls can deform, ruining

the bearing Ball bearings are often used in individual cages.

-

A flexure bearing is a bearing which allows motion by bending a load element. A typical flexure bearing is just one part, joining

two other parts. For example, a hinge may be made by attaching a long strip of a flexible element to a door and to the door

frame. Another example is a rope swing, where the rope is tied to a tree branch. Flexure bearings have the advantage over most

other bearings that they are simple and thus inexpensive. They are also often compact, lightweight, have very Low friction, and

are easier to repair without specialized equipment. Flexure bearings have the disadvantages that the range of motion is limited,

and often very limited for bearings that support high loads

-

Fluid bearings are bearings that support their loads solely on a thin layer of liquid or gas. They can be broadly classified into two

types: id dynamic bearings and hydrostatic bearings. Hydrostatic bearings are externally pressurized fluid bearings, where the

uid is usually oil water or air, and the pressurization is done by a pump. Hydrodynamic bearings rely on the high speed of the

journal (the part of the shaft resting on the id) to pressurize the flid in a wedge between the faces. Fluid bearings are

frequently used in high load, high speed or high precision applications where ordinary ball bearings would have short life or

cause high noise and vibration. They are also used increasingly to reduce cost

-

A magnetic bearing is a bearing that supports a load using magnetic levitation. Magnetic bearings support moving parts without physical contact. For instance, they are able to levitate a rorating shaft and permit relative motion with very low friction and no mechanical wear. Magnetic bearings support the highest speeds of all kinds of bearing and have no maximum relative speed. Passive magnetic bearings use permanent magnets and, therefore, do not require any input power, but are difficult to design due to the limitations described by Earnshaw’s theorem. Techniques using diamagnetic materials are relatively undeveloped and strongly depend on material characteristics. As a result, most magnetic bearings are active magnetic bearings, using electromagners which require continuous power input and an active control system to keep the load stable. In a combined design, permanent magnets are often used to carry the static load and the active magnetic bearing is used when the levitated object deviates from its optimum position. Magnetic bearings typically require a back-up bearing in the case of power or control system failure.

-

Needle roller bearings are special roller bearings having slender cylindrical rollers that enable them to bear highest load capacity for a given radial space of all rolling-element bearings. Needle roller bearings are ideal for applications where high radial load carrying capacity is required but radial space is limited. Such bearings also suit applications where high rotational speed is involved but cannot accommodate axial loads. Compared to the ball bearings, needle bearing have a large surface area that is in contact with the bearing outer surfaces. Additionally they are more compact because there is less difference between the diameter of the shaft and the diameter of the bearing. Thrust needle bearings are flat and use a radial pattern of needles while radial needle bearings are cylindrical and use rollers parallel to the axis of the shaft. Needle bearings are primarily used in engine components like pumps, compressors, rocker arm pivots, and transmissions.

-

A plain bearing is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore the journal (ie the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of lat surfaces designed to allow motion. Plain bearings, in general, are the least expensive type of bearing. They are alsa compact and lightweight, and they have a high load-carrying capacity.

-

Roller bearings use cylinders instead of spheres that means the contact between the inner and outer race is a line not a point Thus the load is spread over a larger area enabling the bearing to handle greater loads than ball bearings. Roller bearings are used in conveyer belt rollers where they hold heavy radial Loads, however these bearings are not designed to handle much thrust loading.

-

Rolling bearing is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two bearing rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with litte sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone black on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is

moved to the front where the block then rolls on to it It is possible to imitate such a bearing by placing several pens or pencils on atable and placing an item on top of them.

-

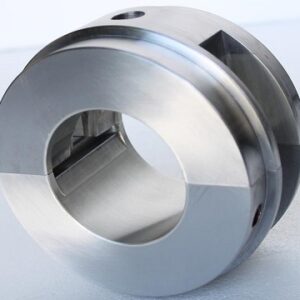

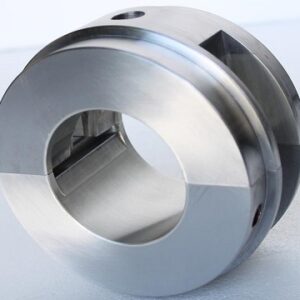

Spherical Roller Bearing Rollers used in spherical roller bearings are thicker in the middle and narrow at the ends, and its race is

shaped to match. They can adjust to support misaligned loads. The construction of spherical rollers are complex and difficult to

produce so they are expensive. Apart from that these bearings have higher friction compared to ball bearing because different parts of the spherical rollers run at different speeds on the rounded race. Thus there are opposing forces along the bearing/race contact increasing the friction. Spherical bearings are used in numerous applications where rotational motion changes the alignment of ts axis of rotation. Important uses of spherical bearings have been in car suspensions, computer mouse, heavy

machinery, sewing machines, drive shafts, etc

-

Tapered roller bearings use conical rollers that run on conical races. Both the inner and outer raceways are segments of cones and the rollers are also made with a taper. Unlike other roller bearings, they support both radial and axial loads, and are able to carty higher loads. The conical geometry of tapered roller bearings provide a larger contact patch, which allows greater loads to be carried as compared to spherical (ball) bearings. The geometry ensures that the tangential speeds of the surfaces of each of the rollers are same as their raceways along the whole length of the contact patch and no differential scrubbing occurs. This greatly reduces rolling friction and avoids rapid wear. Taper roller bearings are used in the wheel bearings of most trucks, buses, cars, and so on Due to manufacturing complexities, tapered roller bearings are generally more expensive than ball bearings

-

Thrust bearings are a particular type of rotary bearing thar allow rotation between parts used but they are designed to support axial loads like vertical shafts for which spherical, conical or cylindrical rollers are used. They are used in gear sets like in car transmissions between gears and between the housing and the rotating shafts. Thrust bearings are of different varieties. Ball thrust bearings are composed of ball bearings supported in a ring. Thrust roller bearings are made of small tapered rollers arranged so that their axes converge at a point on the axis of the bearing